source:Other information release time:2022-11-15 Hits: Popular:PCB Assembly company

Cut the circuit board into the external dimensions required by customers with CNC molding machine (or die punch). When cutting, use the pin to fix the circuit board on the bed (or mold) through the previously drilled positioning hole for forming. After cutting, the golden finger shall be chamfered to facilitate the insertion and use of the circuit board. For multi chip formed circuit boards, X-shaped break lines (called V-Cut in the industry) should be added to facilitate customers to split and disassemble after plug-in programs. Finally, clean the powder on the circuit board and the ionic pollutants on the surface.

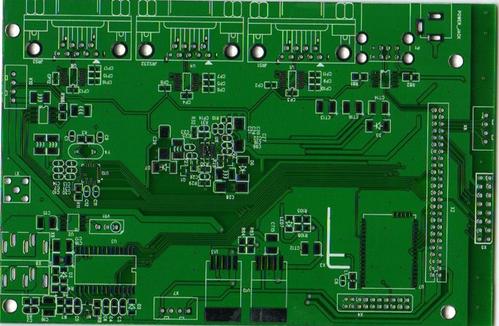

Final inspection package

Before packaging, conduct the final electrical conductivity, impedance test, solderability and thermal shock resistance test on the circuit board. The moisture absorbed by the circuit board in the manufacturing process and the accumulated thermal stress are eliminated by proper baking, and then the vacuum bag is used for packaging and shipping.

Read recommendations:

Metal Core 0.8mm Led Street Light Pcb Aluminium Pcb Board For Led

Lightweight Aluminum PCB Board Green Solder Mask Led Light Pcb Board 3.0mm

Welcome information, we will answer for you quickly