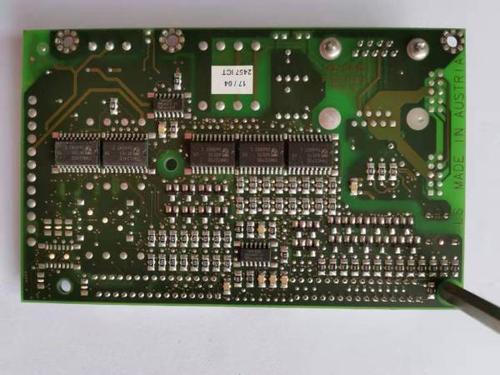

source:Other information release time:2024-03-11 Hits: Popular:PCB Assembly company

"Ink" is liquid metal, and the circuit is printed directly on the paper

"Printing" electronic circuits on paper benefits from breakthroughs in the method of directly printing electronics with liquid metal at room temperature.

Liu Jing introduced that the conventional circuit board manufacturing process is usually time-consuming, consumable, and energy-consuming, while the printed electronics method is like printing text, directly forming conductive lines and patterns on the substrate, which can replace the traditional 7-8 lines. The process is shortened to 3-4 steps, making it fast and flexible.

But this method is limited by "ink". In order to make the printed "ink" conduct electricity, it is often necessary to use conductive polymers or add nanoparticle materials and achieve this through high-temperature curing or specific chemical reactions. The liquid metal printed electronics method takes printed electronics a big step forward. Its basic concept is that "ink" is liquid metal, which can be printed out to become a circuit.

Under traditional technology, if electronic engineers need to change the circuit board, they need to treat it with chemicals and go through etching and other steps to form their own design. The new liquid metal printing method makes the long design process easily accessible. Liu Jing said that they have printed out various relatively simple electronic circuits on paper, and after testing, the conductivity and reliability are good. In theory, particularly complex circuits or electronic components can also be printed. It is understood that printing an A4 paper-sized paper-based circuit board currently only takes more than ten minutes, but for complex circuit patterns, it may take longer.

Liu Jing said that compared with commonly used plastic substrates, paper has the characteristics of low cost, portability, easy degradation, folding, and convenient recycling. It is a green, environmentally friendly, and cheap circuit material.

New method will significantly expand the scope of 3D printing applications

The premise for the realization of printed electronics is that the "ink" should be fluid. In order to find a way to directly produce electronic circuits at room temperature, Liu Jing's team finally overcame this problem through in-depth analysis of the liquid metal transport mechanism. It is worth mentioning that the research team also achieved direct printing of 3D electromechanical composite systems. This means that the new method can not only print flat circuits, but also directly generate three-dimensional complex circuits and their supports.

"Most of the current 3D printing can only print the model itself, and cannot produce devices including electronic functions." Liu Jing said that the liquid metal printing electronics method will significantly expand the application scope of 3D printing technology.

Although paper replaces plastic and direct printing replaces integrated production, although it is still far from reality, what Liu Jing values more is the possibility of personalized manufacturing of future electronic devices behind this concept. Experts believe that this technology is expected to change the rules of traditional electronic circuit manufacturing. The personalized circuit design method has a large application space in electronic engineering, personalized electronic component design and manufacturing processing, creative design, etc. Liu Jing believes that this technology is also expected to occupy the electronic paper market and flex its muscles. According to IDTechEx, a market research consulting firm headquartered in Cambridge, England, the e-paper market was estimated to be approximately US$16 billion in 2013, and this number will grow to nearly US$77 billion in 2023.

In the future, electronic manufacturing may not be in factories, but in offices or homes. This is the future picture drawn by Liu Jing.

"It is of great significance that paper can be used as an integrated carrier for electronic components." Liu Jing believes that the current paper carrier still has weaknesses such as water absorption and insufficient strength, but it has great potential. As the technology is improved, more types of printed circuits will be developed. Paper can also enable more applications.

At present, large-scale integrated circuit production is still the mainstream, with mature technology and scale and cost advantages. Based on the liquid metal printed electronics method, there is still a long way to go to achieve large-scale application.

One is the control of the dosage of metal “ink”. In addition, the types of liquid metal are very limited, and to achieve complex designs, you have to rely on the interactive and automated use of multiple "inks." In terms of hardware development, it is necessary to improve the automation level of printing equipment. Only by developing a desktop automatic printing system wi

Read recommendations:

Immersion Gold IPC Class 3 PCB Double Sided Green Solder Mask 4mil 1.6mm

Halogen Free FR4 Multilayer Printed Circuit Board 1.6mm 10mil Impedance Control

Metal Core 0.8mm Led Street Light Pcb Aluminium Pcb Board For Led

Welcome information, we will answer for you quickly