source:Other information release time:2023-05-06 Hits: Popular:PCB Assembly company

1. Electrolyticni/AU

2.OSP board (OrganicsoldrabilityPreservatar)

3. silver plates (Immersionag)

4. Electrolessni/AU, Enig)

5. Immesiontin

6. Spray tin board

1. Gold -plated board

The cost of gold -plated board process is the highest among all plates, but the most stable among the existing plates currently, and the most suitable board for lead -free processes, especially in some high unit prices or high -reliability electronic products. Board as a substrate.

2.OSP board

The OSP process is the lowest cost and easy to operate, but this process must be assembled to modify the equipment and process conditions and the processing conditions of the process, so the popularity is still poor. Using this type of board, after the high temperature heating, it is pre -covered on the PAD. The protective membrane is bound to be damaged, resulting in a decrease in welding, especially when the substrate is more serious after the secondary welding is welded. Therefore, if the process is needed to go through another DIP process, the DIP terminal will face the challenge of welding.

3. Silver board

Although the "silver" itself has a strong migration, it leads to the leakage situation, but today's "dipping silver" is not a simple metal silver in the past, but the "organic silver" co -plated with organic matter is therefore able to meet the future. Demand in the lead process, its welding life is longer than the OSP board.

4. Golden board

The biggest problem with this type of substrate is the problem of "black pads", so many large manufacturers in the leading process do not agree to use it, but most domestic manufacturers use this process.

5. Tinflag board

Such substrates are easy to pollute and scratched, and the process (FLUX) will oxidize discoloration. Most domestic manufacturers do not use this process, and the cost is relatively high.

6. Spray tin board

Because COST is low, welded, good reliability, and the strongest compatibility, but this welded tin spray plate is not used because of lead. Therefore, the lead -free process cannot be used.

In addition, the "tin silver copper spray tin board" is difficult to use this process, so the characteristics of the characteristic data are difficult.

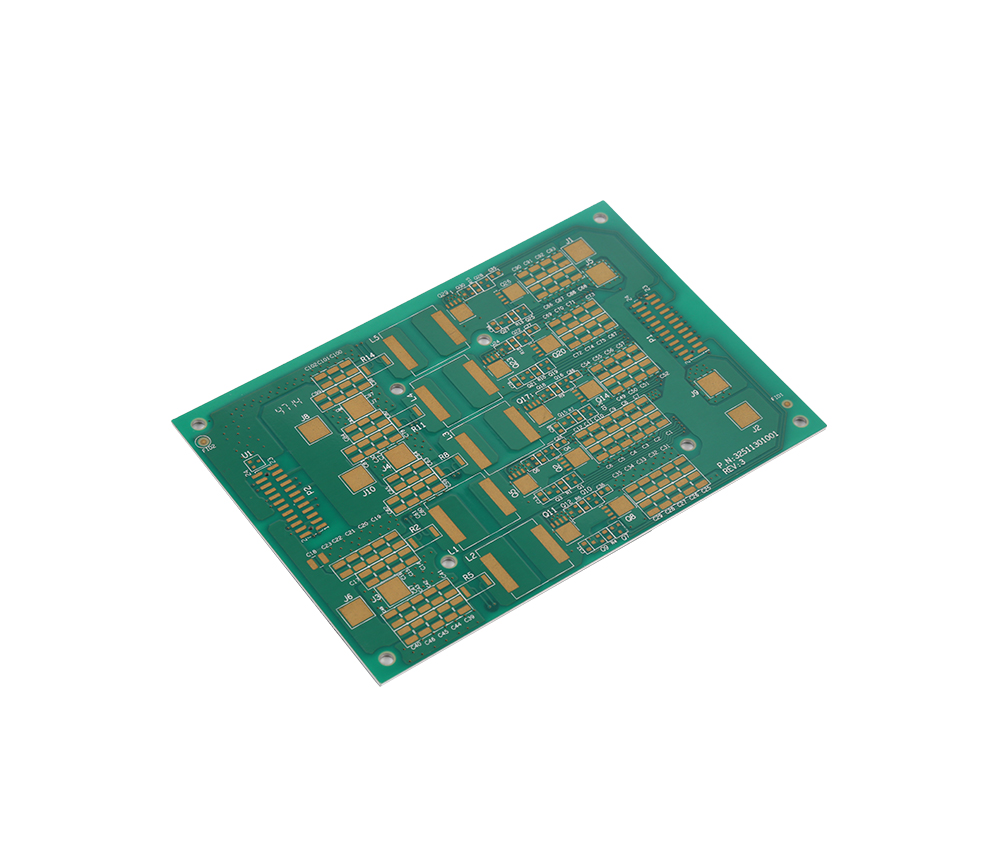

As a part of the whole machine, a PCB generally cannot form an electronic product, and there must be problems with external connections. For example, between PCB, PCB, and boarding components, between PCB and device panels, electrical connections are needed. The use of reliability, craftsmanship and economic best coordination is one of the important contents of PCB design. Today, discuss the PCB plug -in connection method.

In more complicated instruments, plug -in connection methods are often used. This "building block" structure not only ensures the quality of product mass production, reduces the cost of the system, and provides convenience for debugging and maintenance. When the device fails, the maintenance personnel do not have to check the component level (that is, the cause of the failure caused by the check, trace the roots to the specific component. This work takes a considerable time), as long as it is judged which board is abnormal, it is as if it is abnormal. It can be replaced immediately, eliminating the fault in the shortest time, shortening the stop time, and increasing the utilization of the equipment. The replacement of the circuit board can be repaired within a plenty of time and is used as spare parts after repairing.

1. Standard pincture connection

This method can be used for PCB's external connection, especially in small instruments. Two PCBs are connected by standard pins. Two PCBs are generally parallel or vertical, which is easy to achieve mass production.

2. PCB socket

This method is made from the PCB edge. The plug part is designed according to the size of the socket, the number of contacts, the contact distance, the position of the positioning hole, etc., so that it is matched with the special PCB socket.

When making the board, the plug part is placed in gold, which improves wear resistance and reduce contact resistance. This method is simple, with good interchangeability and maintenance performance. It is suitable for standardized large -scale production. The disadvantage is that the PCB cost is improved, and the accuracy and process of PCB manufacturing are high; the reliability is slightly poor, and it is often inaccurate because the plug part is oxidized or aging of the socket reed. In order to improve the reliability of the external connection, the same lead is often led to the same or on both sides of the circuit board.

Read recommendations:

Welcome information, we will answer for you quickly